Unpacking the Costs: Understanding the Complexities of Buying Furniture in Bulk

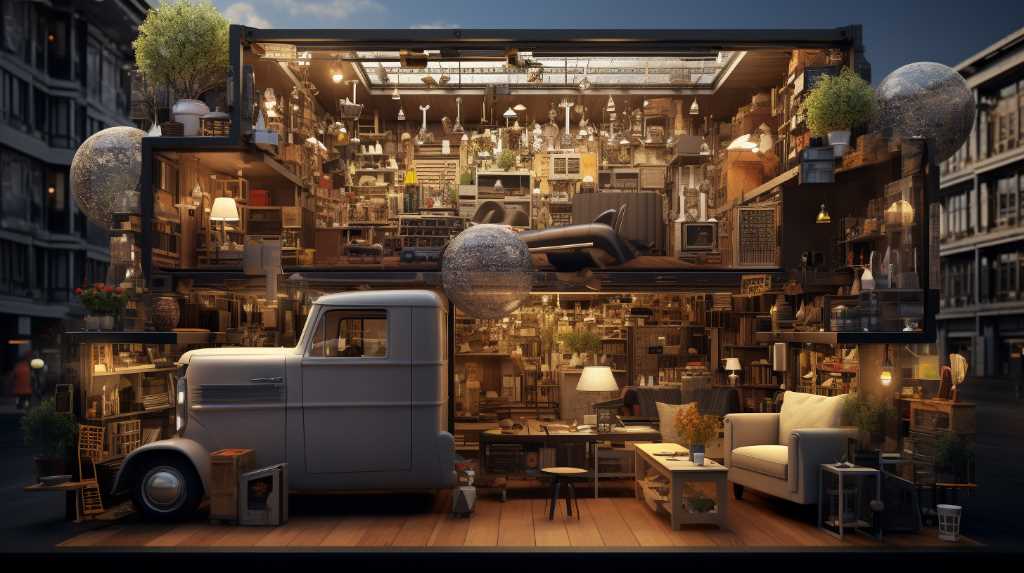

The market for bulk furniture purchasing is a web of factors that influence the final prices businesses and institutions encounter. ‘Unpacking the Costs: Understanding the Complexities of Buying Furniture in Bulk’ thoroughly investigates the numerous elements that shape the expenses involved.

This report scrutinizes the impact of material quality on both longevity and visual appeal of furniture. It also examines how the complexity of design and the standing of a brand can increase the overall cost.

The analysis takes into account the effect of buying in large quantities and the choices for customization that can alter the financial outlay. Additionally, it sheds light on the logistical challenges and the regulations of international trade that are critical components in determining the end price.

Grasping these intricacies is vital for purchasers aiming to make well-informed choices when acquiring furniture in large volumes.

Material Quality Factors

Material Quality Considerations in Bulk Furniture Purchases

The visual charm of a piece of furniture is obvious at first glance, but when making bulk furniture purchases, the significance of material quality should not be underestimated. It’s a critical factor that greatly influences both the longevity and cost-effectiveness of the investment. Buyers tasked with making large-scale purchases need to assess the materials for more than their outer qualities, considering the overall composition and projected durability of the furniture.

For example, wood is a common choice, but options within this category vary greatly. Solid hardwoods are known for their strength and longevity, whereas engineered options like MDF or particleboard offer a more cost-effective solution with different performance metrics. Choosing between these wood types isn’t just about preference; it’s about making informed decisions that consider both budget constraints and the furniture’s intended use.

Other materials like metal, glass, and plastics also play a significant role in the decision-making process for furniture procurement. Metals are valued for their structural support, yet they differ in weight, tensile strength, and their ability to resist corrosion—all of which affect shipping costs and environmental suitability. Glass adds a touch of sophistication to furniture but requires a close look at its thickness and safety features to ensure it can stand the test of time. Plastics, with their adaptability and lower costs, must be evaluated for their longevity and how well they maintain their appearance after prolonged use.

A strategic approach to purchasing involves a detailed cost-benefit analysis. It’s not just about the upfront savings on cheaper materials; consideration must also be given to the future expenses associated with maintenance, potential replacement, and the impact on customer satisfaction throughout the furniture’s lifespan. Such an analytical perspective is necessary to confirm that the price aligns with both short-term requirements and the anticipated long-term value.

Buyers must remain vigilant, questioning assumptions, and demanding comprehensive data to make informed decisions. This approach aligns with the rigor of investigative journalism, aiming to uncover the full story behind the materials that will ultimately support the use and enjoyment of the furniture for years to come.

Design and Brand Influence

Design and brand reputation hold considerable sway over bulk furniture purchasing decisions. Buyers considering large-scale furniture acquisitions need to scrutinize how design and brand recognition resonate with their intended audience, impact daily operations, and contribute to financial performance. A brand with a strong reputation may often set a higher price point, reflecting its perceived quality and prestige. This can affect buyer preferences and could justify a higher cost. Nonetheless, it is vital for buyers to assess if this perceived value is in line with their strategic goals and whether it will provide a worthwhile return on investment.

Looking at design, the aesthetic and functional properties of furniture extend beyond mere appearance; they are critical to user contentment and efficiency. Choosing design features wisely can mean furniture remains functional and appealing over time, potentially saving money by reducing the need for frequent replacements or upgrades.

When it comes to cost-effective procurement, the challenge lies in finding a balance between the appeal of well-known brands and the practicality of their design against budget limits. This requires a thorough evaluation of how brand value and design quality contribute to the greater objectives of the buying organization, with every dollar spent aimed at adding real value to the organization.

Quantity and Customization Costs

When buying furniture in large quantities, the number of items and the degree of personalization are critical factors that affect pricing. Larger orders often mean lower prices per unit because fixed costs are spread across more products and resources are used more efficiently. However, adding custom elements can change the equation. Tailoring products requires extra design work, unique materials, and potentially different manufacturing methods, all of which can raise costs depending on how complex and specific the customizations are.

Smart purchasing requires an in-depth look at the pros and cons of standard versus bespoke furniture. Companies need to consider the advantages of custom designs, like reinforcing brand identity and improving the user experience, against the additional expenses they bring. It’s wise to perform a thorough cost versus benefit review to measure the real value of customization against its financial toll.

The key is to find the right balance between the number of items and the customization degree, aiming for a middle ground that upholds quality and customer happiness while keeping the budget intact. Bulk purchasers should work with their suppliers to identify ways to save costs, such as using modular designs or flexible manufacturing methods that can include custom features without a significant price hike.

Logistics and Trade Implications

The cost of purchasing furniture in large quantities isn’t just about the sticker price. It’s also about understanding the complexities of logistics and the ever-changing landscape of trade policies. When you’re buying bulky items like furniture, the logistics of getting those items from the manufacturer to your doorstep can drastically affect your budget. It’s not just about picking the cheapest option; it’s about finding the best value.

Choosing the right mode of transport—whether it’s by sea, rail, road, or air—is a decision that must be made after a thorough analysis of the expenses, the time it will take, and the reliability of the service. The aim is to reduce what’s known as the landed cost, which is the total price of a product once it has arrived at a buyer’s doorstep.

Trade policies are another critical factor that can influence the cost of furniture. Tariffs, import duties, and trade agreements all play a role in determining the final price you pay. Buyers need to keep up-to-date with global trade developments, such as shifts in international relationships or the introduction of new agreements that can change costs in unexpected ways. Sometimes, purchasing from a country with beneficial trade agreements can make up for higher production costs because of lower import duties.

Being aware of costs means more than just looking for the lowest quote. It involves understanding the entire logistics chain, including any potential delays or issues, and the geopolitical environment that could impact delivery times and overall costs. This thorough approach allows companies to plan for extra expenses and tailor their buying strategies to ensure they’re getting the right mix of quality, cost, and delivery timing.